Labnet Celebrates 100 Years of Stirring!

26 Oct 2017

The First Magnetic Stirrer

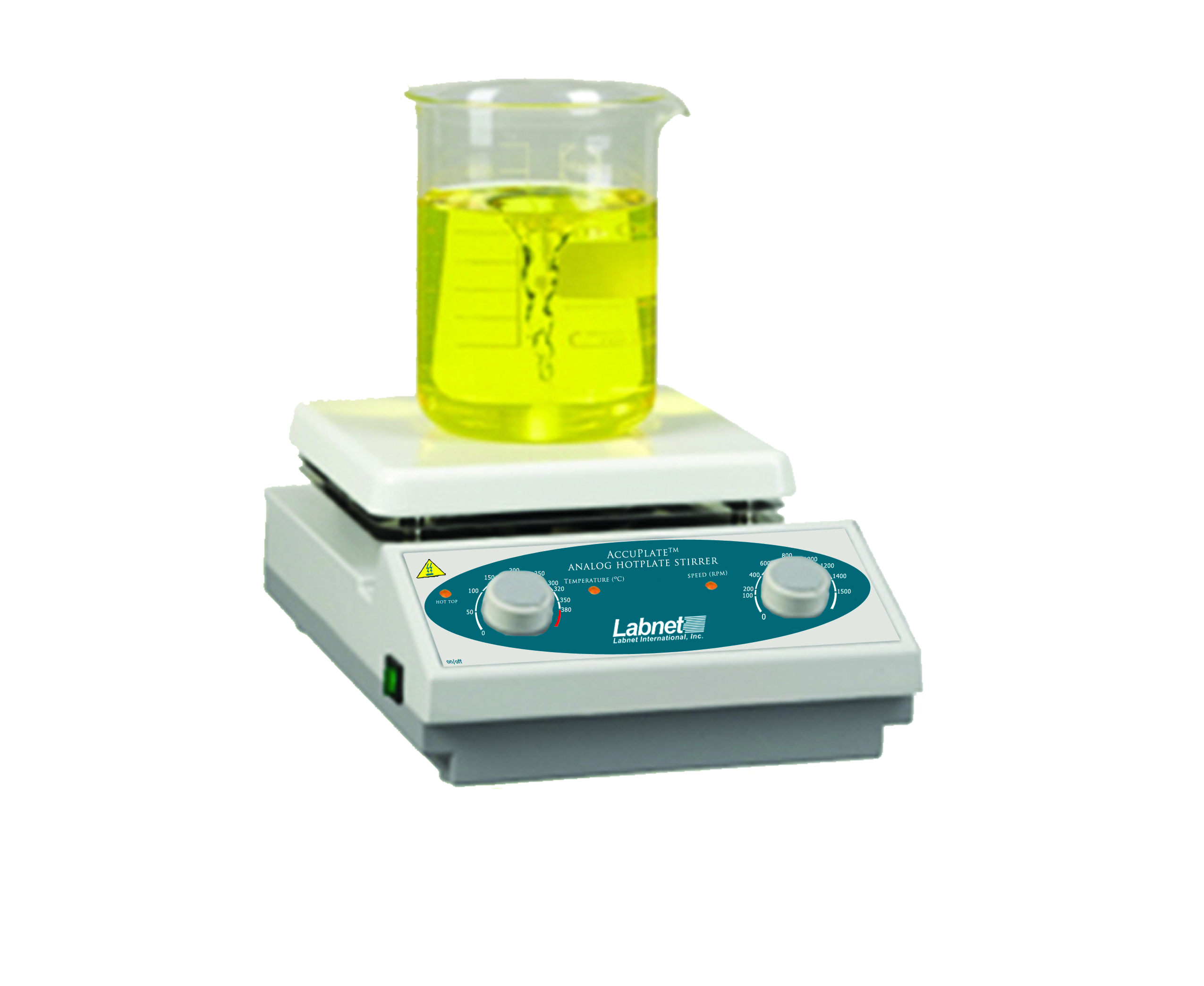

The first magnetic stirrer was patented by Richard Stringham of Utah in 1917. The inventor nicknamed the stir bar a “Flea” because of the way it jumped and spun in the flask. Even after a Century of technological advancement, today’s lab stirrers still resemble the original design. An electrical field under the base plate oscillates causing the magnetic stir bar to spin.

The stirrer quickly evolved once it hit the market. Integration with a hotplate was a bold step towards laboratory automation.

- 1939: Heating is added to the stirrer.

- 1944: Coatings of glass, porcelain and plastic are added to prevent the stirrer from compromising solutions.

Rocking is another gentle method of agitation that performs membrane-based assays and washings. Labnet International offers many options for both low and high-volume rocking with features like double platforms and adjustable tilt settings for all of your application needs.

Shaken, Not Stirred

Shaking is a more vigorous method of mixing than either stirring or rocking. The increased agitation has a secondary benefit as well: oxygenating samples. This is particularly useful in biological studies. These advancements in automated stirring freed researchers to explore biological processes, creating demand for even more vigorous mixing and aeration.

The middle of the Twentieth Century saw great advancements in bacterial isolation and culture. Rutgers University grad students were dedicated to isolating an antibiotic-producing bacterium but achieving inconsistent results. They identified their makeshift test tube shaker as the weak link in their process chain. The shaking device that answered that need was then used in the Nobel Prize winning isolation of streptomycin.

- 1949: Rutgers University worked with manufacturers to develop first shaking device.

- 1952: Nobel Prize awarded for effective use of Streptomycin against Tuberculosis.

Shakers were used for 20 years before researchers fully understood the implications of shaking in the fields of Bioengineering and Biochemical processes. Parameters were now being documented for shaker speed, orbit diameter and flask angle.

- 1960’s: Focus on oxygenation led to advancements in mammalian cell culture.

Shaking Leads to Vortexing

Vortex mixing is a very vigorous liquid mixing technology for small vials of liquid. During vortexing, a soft rubber cup sits atop a vertical shaft. The rubber cup is the point of contact for the sample vial. When the vial is pressed against the rubber cup, the spinning force transfers to the liquid and the cyclonic action is visible instantly.

Are you Mixed Up about Mixing Technologies?

With all of these options available, it can be overwhelming to select the right lab equipment for your bench. Labnet International makes those selections easier with application-specific information and cost-effective products. All of our stirrers, shakers, rockers and vortexers share a firm foundation of sound engineering and quality construction.

- Digital controls provide accurate performance.

- Precision balance and counter-balance ensure long motor life.

- Sound engineering results in quiet, low-maintenance operation.

- Durable analog versions are ideal for educational use.

A wide range of set points for all parameters offer precise control of temperature, over-temp safety, speed, stroke length and process time.

Whether you have samples that need to be gently rocked or completely homogenized, Labnet International has the product selection for you. Check out our full line of laboratory agitation products for products ranging from small, workstation vortexers to stacking, high-volume incubators that heat and shake production batches of flasks. Or, speak to your Labnet International consultant today to get help identifying the right technology for your bench!